When you talk about performance upgrades, most construction machine owners have the mindset that upgrades are expensive. You probably think about big spends & even costly parts replacements. In reality, improving performance doesn’t always mean spending heaps of cash. You can make performance enhancements without digging a hole in your pocket.

For fleet owners & contractors, improving a fleet’s performance via cost-effective performance upgrades is a great strategy. This prevents spending big & ensures your machines offer the best ROI. Upgrades aren’t about replacing parts, but also tuning a part that already works.

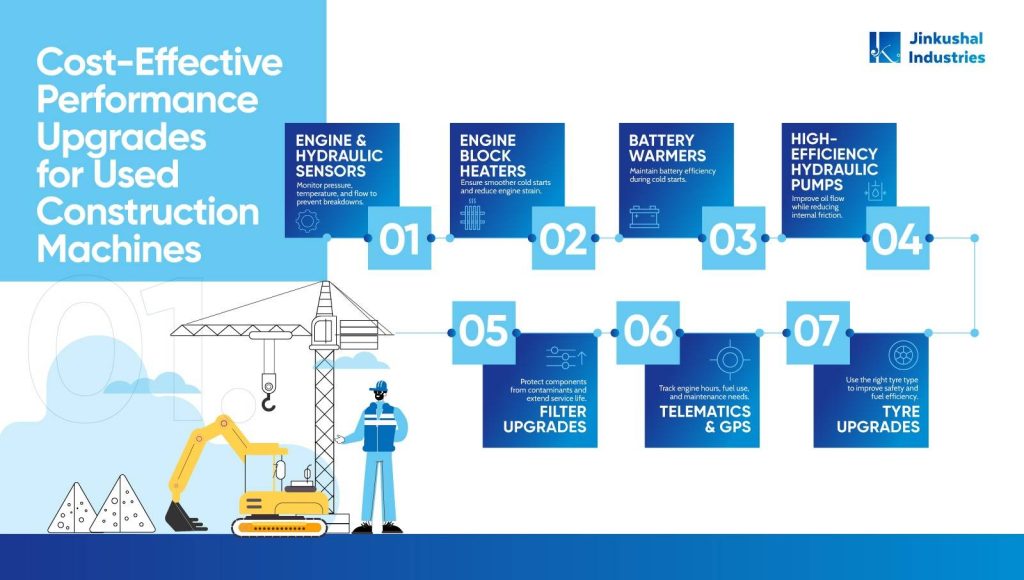

10 Cost-Effective Performance Upgrades For Used Heavy Machines

1. Engine & Hydraulic Sensors

Used & refurbished machines often miss out on specialised engine & hydraulic sensors to monitor performance & load control. Upgrading to advanced engine & hydraulic sensors enhances precision, load control & operational safety, helping these components monitor pressure, temperature, & flow to avoid breakdowns & repairs.

2. Engine Block Heaters

In colder regions or winter, engines in heavy machines need some time to heat up & let the lubricant flow all over the internal engine parts. An aftermarket engine block heater is among the affordable upgrades for heavy equipment that keeps the engine ready by maintaining the optimal oil viscosity for smoother starts, reduced fuel consumption & reduced engine strain.

3. Battery Warmer & Blankets

Cold starts lead to higher fuel consumption, reduce battery efficacy & downtime. A battery warmer maintains optimal charge levels to make sure power delivery remains constant in cold mornings. It’s one of the simplest performance upgrades you can do to increase engine reliability & performance.

4. High-Efficiency Hydraulic Pumps

Although modern machines use advanced pumps that require less energy to operate, many used machinery still employs older ones. Newer aftermarket high-efficiency hydraulic pump uses modern engineering to ensure better oil flow & less internal friction, while providing increased power & less fuel consumption.

5. Filter Upgrades

Your heavy machinery heavily relies on a fuel, hydraulic fluid, air & lubricant filter to avoid dust, debris & contaminants entering the components & causing damage. Aftermarket filters protect these components & increase performance. Many quality after-market filters offer a longer life than those made by OEMs, making it one of the best affordable upgrades for heavy equipment.

6. Telematics & GPS

GPS & telematics enable owners to track vehicle performance, gain important usage insights, predict maintenance needs, and utilise route optimisation to achieve the best fuel economy possible. When you install telematics in a used machine, perks like engine hour monitoring, fleet management, fuel consumption tracking, coolant temperature monitoring, and oil pressure & idle time tracking help you take actions & increase performance.

7. New Tyres

Many equipment owners use the wrong tyres & the impact it puts negatively is beyond imagination. Construction machine tyres are available in many types, like bias, radial & solid, plus different tread depth & patterns. Each tyre has a different purpose & the wrong tyre can reduce performance, safety & fuel economy.

8. Upgraded Cooling Systems

If your machine is old, it may easily overheat during heavy applications. Solve this issue by upgrading the cooling system. Replace old radiators, coolant hoses & choose high-performance coolant fluids. These performance upgrades will help the engine & hydraulic system maintain optimal temperature, avoid costly repairs, downtime & achieve the best performance.

9. Upgraded Lights

Bright lighting increases visibility during dark hours & helps approaching vehicles know about the presence. Aftermarket lights are a great way to increase safety & productivity after dark. LED lights consume less energy than traditional bulbs while offering better illumination. This low-cost upgrade can help you work on projects at night while keeping safety in check.

10. Wear Part Upgrades

Investing in durable wear components like cutting edges, bucket teeth, & undercarriage parts can significantly improve your machine’s performance & reduce the replacement frequency, since these are made for longer periods. Investing in quality parts offers better uptime & efficiency, making them one of the most cost-effective performance upgrades.